Threads that change colour in response to certain gases

A NEW method for dying threads could be used to create smart clothing that changes colour in the presence of potentially harmful gases.

Colour-changing threads have the potential to become an important safety aspect if woven into clothing. The gas-sensing technology would be an advantage to low resource communities as the textiles don’t require specialised training or equipment, thus making them more affordable and easy to use.

Researchers at Tufts University, US, have developed a process that traps dyes in threads so that the dye can be used to detect gases. They tested three different dyes; bromothymol blue (BTB), methyl red, and MnTPP, which are dyes that can react with gases with acid or base properties. MnTPP and BTB can be used to detect ammonia (a base), and methyl red can be used to detect hydrogen chloride (acid). These gases are commonly released in fertiliser and chemicals production.

To trap the dye in the thread, the thread was dipped in the dye and then treated with acetic acid. This makes the surface of the thread coarser and swells the fibre, allowing more binding interactions between the thread and the dye. The thread was then coated with polydimethylsiloxane (PDMS) which creates a seal around the thread and dye, allowing the thread to repel water and stopping the dye from leaching. The PDMS is also gas permeable. “While the PDMS sealant is hydrophobic and keeps water off the thread, the dissolved gases can still reach the dye to be quantified," said Rachel Owyeung, lead author of the study.

"The dyes we used work in different ways, so we can detect gases with different chemistries," said Sameer Sonkusale, Professor of Electrical and Computer Engineering at Tufts’ School of Engineering. “But since we are using a method that effectively traps the dye to the thread, rather than relying so much on binding chemistry, we have more flexibility to use dyes with a wide range of functional chemistries to detect different types of gases."

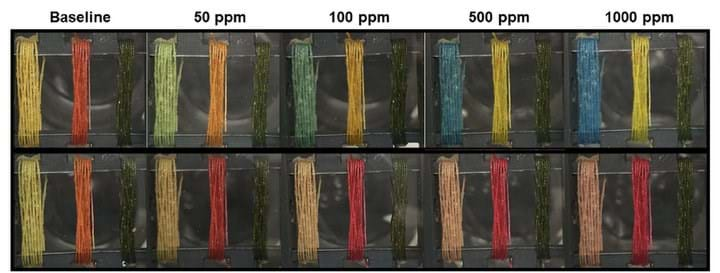

The dyes on the threads change colour when exposed to the gases. For example, the BTB is a weak acid and when exposed to ammonia, the thread changes from yellow to blue. The threads can detect gases as low as 50 ppm. The results were verified with spectroscopic techniques, but can be seen in optical images. There is also the possibility of using a smartphone to quantify the colour changes for increased precision or if more complex colour signatures need to be detected. "That would allow us to scale up the detection to measure many analytes at once, or to distinguish analytes with unique colorimetric signatures," said Sonkusale.

“As dissolved gas sensors, we imagine smart fabrics detecting carbon dioxide or other volatile organic compounds during oil and gas exploration as one possible application,” added Owyeung.

Scientific Reports http://doi.org/c4vc

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.