Researchers source and develop PPE to protect surgeons

RESEARCHERS at Imperial College London, UK, have sourced and developed personal respirator equipment to help address a shortage and protect surgeons and medics in the UK during operations on coronavirus patients. The equipment has been successfully used for high-risk procedures at NHS hospitals.

Many Covid-19 patients have been admitted to intensive care suffering from viral pneumonia and respiratory distress syndrome. Subsequently, as their illness develops some patients require a tracheostomy, a procedure in which a tube is placed into the trachea to aid breathing. During operations, surgeons and other healthcare professionals are at risk of infection.

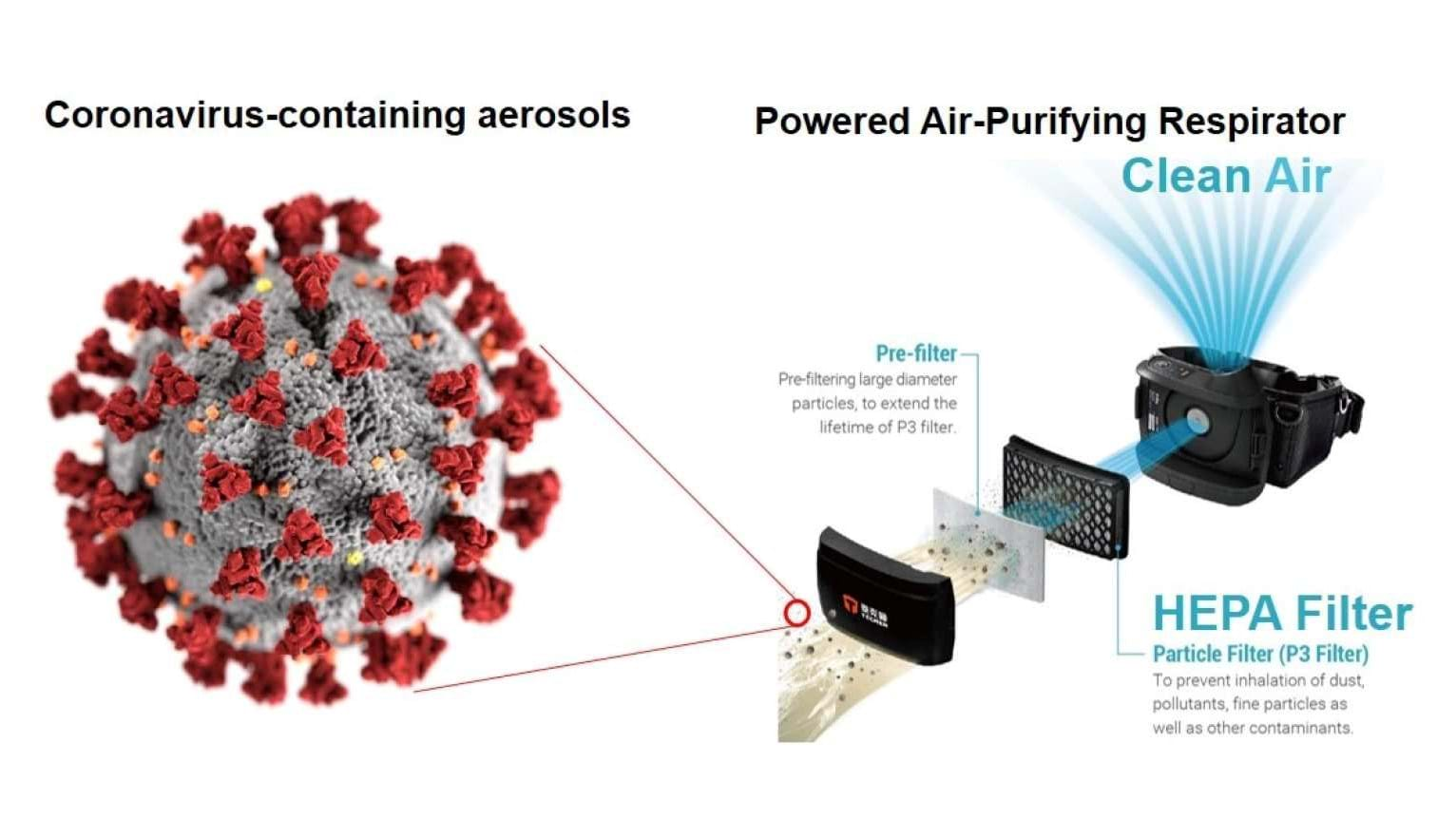

Powered air-purifying respirators (PAPRs) are reusable, enhanced personal protective equipment (PPE). In these systems, a battery-powered respirator filters surrounding air and removes hazardous particles and contaminants via a high-efficiency particulate air (HEPA) filter. It incorporates a hood that protects the head and covers the shoulders.

PAPRs have proved to be effective in reducing the risk of coronavirus infection, and they have been widely used and listed as a protective option against the coronavirus by many international health organisations. However, there has been a significant shortage of PAPR PPE in the UK.

After discovering that PAPRs have been widely used in the UK welding industry the team at Imperial sourced several commercially-available PAPRs and respirative hoods from a variety of UK suppliers, and assembled prototypes. After screening and evaluation, the team chose to move forward with TECMEN PAPRs using P3-level HEPA filters from UK distributor Weldfast UK. Weldfast is an equipment wholesaler and manufacturer which serves the welding industry.

Additionally, the team contacted Chinese manufacturer TECMEN, which donated ten upgraded PAPR systems and accessories, including front cover and reusable hoods. The manufacturer also arranged rapid delivery to Imperial. Using the donations, the team upgraded its prototypes. Further systems were purchased.

Features of the upgraded systems include certified high capture efficiency (>99.996%); a battery duration of up to nine hours that requires only one hour recharge time; a clear visor with anti-fog so vision is always clear; and comfortable hoods. Additionally, the manufacturer can supply key consumables in the system (prefilters and filters that require daily disposal) and accessories in 5–7 days.

The team has now established a supply chain by connecting the manufacturer in China and UK distributor Weldfast. The collaboration allows UK hospitals to purchase large volumes of equipment at reasonable prices, at a time when resources are scarce.

With the support of its industry partners the project has donated 100 sets of PAPRs to Imperial College NHS Trust Healthcare Hospitals and other hospitals in London. The equipment has proved particularly useful for medics during throat surgeries.

Neil Tolley, Head of the Ear, Nose, and Throat (ENT) division at Imperial College NHS hospitals, said: “The PAPRs have been a ‘game changer' as they have facilitated a change in the management of ENT emergencies and have permitted us to recommence airway and emergency surgery to pre-Covid principles, and ultimately minimised risk for medical staff, permitting us to perform more potentially high risk procedures.”

The collaborative PAPR project was initiated in mid-March and coordinated by Qilei Song, Lecturer in the Department of Chemical Engineering. It involves collaboration between scientists and engineers at Imperial, medical staff in the UK and in China, Imperial NHS trust, and manufacturers and suppliers in China and the UK.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.