Lowering emissions from ammonia production with electrolysis

A NEW method to produce ammonia via electrolysis can improve the process while also lowering emissions.

Ammonia is needed to make fertilisers and is typically produced from nitrogen and hydrogen via the Haber-Bosch process. The hydrogen is typically provided via steam methane reforming. The production of ammonia using conventional fossil fuels methods is responsible for around 1.8% of global CO2 emissions. It is also possible to produce ammonia using electrochemical processes at ambient temperatures, although this technology can’t yet produce ammonia at scale.

One of the challenges is the energy required to break the strong N2 triple bond. Another issue is that the N2 reduction reaction (NRR) competes with the hydrogen evolution reaction (HER), resulting in more hydrogen produced than ammonia.

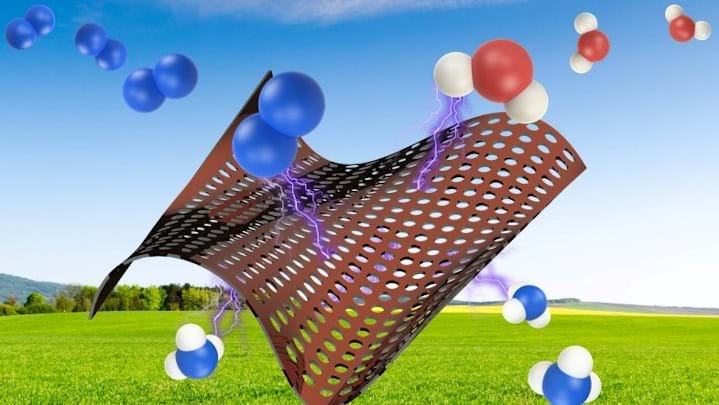

A team of researchers from the University of Illinois at Chicago and the University of Minnesota, US, has identified how the activity and selectivity of the NRR can be improved by assessing the catalyst design, the engineering of the electrolyte, and optimisation of the electrochemical cell. They used porous carbon paper that had been coated with a copper catalyst to produce ammonia from dinitrogen and water.

Unlike the conventional method for ammonia production, the new process doesn’t require hydrogen from fossil fuels. “The electrochemical process uses protons generated from the oxidation of water at the anode to hydrogenate N2 at the cathode,” said Meenesh Singh, Assistant Professor of Chemical Engineering at the University of Illinois Chicago College of Engineering. “In this way, we bypass the need for hydrogen gas as input to the process.”

The new electrolysis method uses similar amounts of energy to the traditional process, which produces an average of 2.8 t of CO2 per t of NH3. Using electricity derived from fossil fuels for the electrolysis process would result in 2.65 t of CO2, but by using renewables the process can have net zero CO2 emissions.

The process produces around 20% ammonia and 80% hydrogen. Singh said: “We are hoping to increase the production of ammonia, but our early efforts so far are promising, and the savings in the carbon emissions are still significant if you were to scale up our process to produce large amounts of ammonia.”

The researchers are also assessing the possibility of using nitrogen from the air rather than a source of purified nitrogen gas. This would result in additional greenhouse gas savings, as nitrogen gas needs to be purified and bottled.

Singh said that the team is currently working with a company to scale up their process. “Our new technology can now produce around 300 mg of NH3 in 1 day using 1 cm2 of electrode. This new catalyst is way more active than any state-of-the-art catalyst. We are now scaling up to produce 1 kg of NH3 per day using our patent-pending electrochemical reactor.”

ACS Catalysis https://doi.org/fp4x

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.