Engineered enzyme digests plastic

AN EXPERIMENT to study a plastic-eating bacterium accidentally created a mutant enzyme that degrades plastic more efficiently.

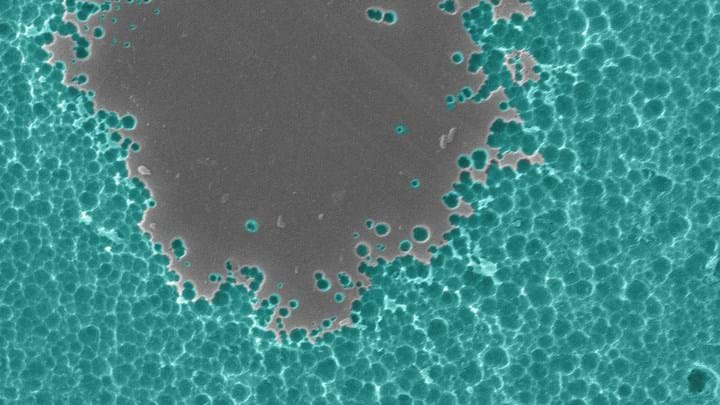

Polyethylene terephthalate (PET) is one of the most commonly manufactured plastics and has a wide range of uses such as in drinks bottles, packaging, and clothing. Most processes use a crystalline PET which is resistant to biodegradation, resulting in plastic that can persist in the environment for centuries. The difficulty in depolymerising PET is due to limited access to ester linkages. This makes it difficult for ester bonds to be broken and therefore for the plastic to be broken down into its constituents. Depolymerisation of PET can be achieved in chemical recycling facilities, but this has high processing costs which leads to PET primarily being recycled mechanically, if at all.

In 2016, a bacterium was discovered at a waste recycling centre in Japan that consumes PET with the help of an enzyme dubbed “PETase”. As PET has only been widely used since the 1970s, researchers were curious as to how the bacterium could have evolved so quickly to use plastic as a food source. In order to understand the capabilities of PETase, the enzyme was examined using X-ray crystallography at Diamond Light Source in the UK, which allowed the researchers to create an ultra-high-resolution 3D model of PETase.

It was previously known that PETase has similar properties to a cutinase enzyme, but the 3D model revealed a striking difference between PETase and cutinase. The active site of PETase, which is where the substrate molecules bind, is up to three times the width that of cutinase. The larger active site allows the enzyme to accommodate the bulky components of PET.

The researchers wanted to test the hypothesis that the changes in the active site resulted from the evolution of the bacterium in a PET-containing environment. To do this, they mutated the active site of PETase to make it more like cutinase.

Instead, they got a surprise when the mutated enzyme turned out to be more efficient at PET depolymerisation than the original form of PETase. They also discovered that their mutant was capable of degrading another type of plastic, polyethylene furandicarboxylate (PEF). PEF is a bio-based plastic that is produced from sugars and while it offers a greener alternative to PET, it also persists in the environment for a long time.

“Although the improvement is modest, this unanticipated discovery suggests that there is room to further improve these enzymes, moving us closer to a recycling solution for the ever-growing mountain of discarded plastics,” said John McGeehan, a professor at the University of Portsmouth who led the research.

Commenting on the research, IChemE Fellow Adisa Azapagic, professor of sustainable chemical engineering at the University of Manchester, said:

“The proposed technology could potentially be useful for plastics recycling. However, this is an early step, with significant further developments needed to demonstrate the process at a scale. A full life cycle assessment would also be needed to ensure that the technology does not solve one environmental problem (waste) at the expense of others. This includes additional greenhouse gas emissions across the reverse supply chain and related climate change impacts.”

Douglas Kell, professor of bioanalytical science at the University of Manchester, commented:

“This is an important advance, and further rounds of evolution, especially in regions away from the active site, should be expected to improve the enzyme yet further. All told, this advance brings the goal of sustainably recyclable polymers significantly closer.”

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.