Costain claims world-first as it completes FEED for Teesside elements of the East Coast CCUS Cluster

COSTAIN has created the first digital record of all the above and below ground assets in the Teesside industrial cluster, which forms part of the UK’s wider East Coast CCUS Cluster. The digital record aims to offer a “single source of truth” to guide development of future projects in the densely populated industrial area.

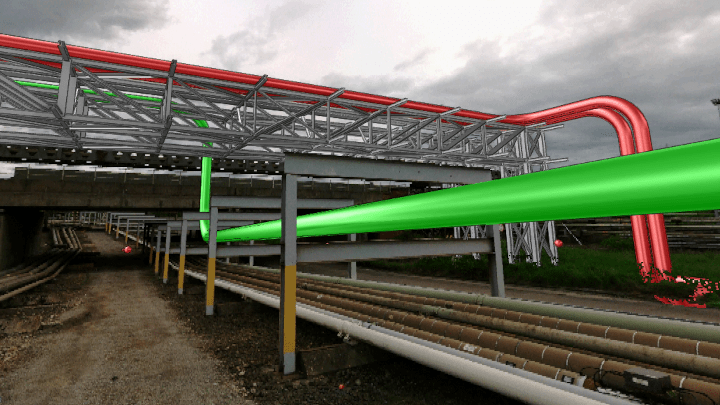

The civil engineering company has also designed what it says is the world’s first wholly above ground vapour phase CO2-gathering network.

Both were part of integrated front-end engineering design (FEED) work that Costain has completed for two key onshore elements of the UK’s East Coast Cluster – Net Zero Teesside (NZT) Power and the Northern Endurance Partnership (NEP) – located in Teesside. Expected to halve the UK’s industrial cluster CO2 emissions, the East Coast Cluster comprises projects in Teesside and the Humber and is set to be operational by the mid-2020s.

Niku Nobakhti, project manager at Costain, spoke to The Chemical Engineer about the challenges that the FEED team faced while designing the above-ground carbon network, as well as the opportunities and challenges presented by developing the Teesside geographical information system.

Above ground

NEP is a joint venture involving BP, Equinor, and TotalEnergies that will provide CO2 transport and storage for the East Coast Cluster. Costain’s FEED work for the partnership focused on design of the onshore CO2-gathering network that will serve Teesside-based carbon capture projects including NZT Power.

Extending around 12 km and with a diameter of around 56 cm, the Costain-designed pipeline can transport around 4m t/y of CO2 which will be stored in the North Sea.

Nobakhti said Costain set the objective that the transport network be above ground. She said: [Teesside is] such a heavily congested area that we couldn't guarantee that we'd be able to bury [the pipeline] all the way through.”

As well as avoiding the risks of trying to bury the pipeline in a congested brownfield environment, keeping it above ground benefits from the economics of relying on existing above ground infrastructure.

It also presented its own challenge, however, with drops in temperature potentially causing the CO2 to go from the vapour phase to the liquid phase, creating liquid dropouts. “What that does is create, or has the potential to create…slug flow, where the liquid coalesces, and then travels through your pipeline as a slug formation,” said Nobakhti.

Costain’s biggest concern was that the forces of the slug movement could lead to ruptures at bends in the pipeline, posing the risk of leaking the colourless greenhouse gas into the environment, while also threatening the health of workers – CO2 is an asphyxiant.

To understand whether the scenario was realistic, the design team relied on modelling methods including fluid modelling and flow assurance modelling. Nobakhti highlighted that for CO2, especially working within the operating envelope, understanding of its behaviour and movement was limited in comparison to conventional oil and gas.

Nobakhti said of their pioneering work: “What we found was that within the transportation of [CO2], any liquid dropouts…it eventually flashes back into gas form so we didn't have the worry about ‘how do we get rid of the slug?’ But we still had to deal with the forces that get created by liquid formation and that process of liquefying and flashing. And that's where we took the pipeline design and started designing to be able to withstand those forces.”

She was unable to provide specifics regarding how the findings impacted design but did note that because slug flow assessment showed that liquid formation could be accommodated in the pipeline and structural design, the engineering team was able to simplify the requirements for the safety system.

A digital legacy

Costain also routed the carbon capture network, saying the key to its success was creating a geographical information system to act as a single source of truth that provides asset information and data from a variety of sources and stakeholders. Creating the system involved extensive laser scanning, topographical information, and ground investigations, to document above and below ground assets at the site.

Nobakhti said that the combination of the Teesside and Humber clusters are heavily polluted, and require large-scale support for decarbonisation. “What we’ve done is produce the first digital records…for [the Teesside] industrial network, that can then be leveraged,” she said.

“Every time we want to build in that area, we’re not going through the same steps…of trying to find out all that information. What we’re hoping is to leave behind a legacy where that information is available for all the different asset owners.”

Meanwhile, Costain’s completed FEED work for NZT Power includes natural gas supply pipework and a high voltage 265 kW power network. NZT Power is a joint venture between BP and Equinor aiming to create the world’s first commercial gas-fired power station with carbon capture technology. It could generate up to 860 MW of low-carbon power, enough for 1.3m UK homes.

NZT Power and NEP aim to take final investment decisions in September, and for commercial operations to begin from 2027.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.