Towards a Circular Chemical Economy: Stakeholders’ Perspectives

Bing Xu, Umit Bititci, Melissa Marques, Mengfei Jiang, and Jin Xuan discuss challenges and motivations

WHAT images come to mind when you think of pollution? Litter-strewn beaches? Plumes of carbon dioxide from industrial chimneys billowing into the air? Exhaust fumes from bumper-to-bumper traffic as far as the eye can see?

All are issues that need addressing – especially as we approach COP26 – if we are to make the necessary changes to achieve net zero and create a more sustainable future. How can the UK’s chemical industry play a role in this important transition, and make chemicals and materials in a more sustainable and circular approach?

While many don’t think about it, most of us interact with the chemical industry on a daily basis. There’s a good chance that, as you read this article, you’ve already done so today: in the shampoo you used in the shower, the plastic bags you used for shopping, the lubricants that keep your car running, and in the agricultural systems that put food on your table, to name but a few.

The problem is that 80% of chemicals are derived from fossil fuels, and refining and manufacturing processes are not always as clean as they could be. This causes issues when the end goods – as is often the case – find their way into the

environment after they have been used.

In an effort to become more sustainable, many industries are seeking to build circular economies that reuse, share, repair, refurbish, remanufacture and recycle to create a “closed-loop” system that minimises the use of resource and creation of waste, pollution and carbon emissions. This is opposed to the open, linear model characterised by a “take-make-use-waste” chain that has prevailed in the chemical sector to date.

The best circular solutions may differ from industry to industry. For instance, remanufacturing – where old, worn, or non-functional items and components are recovered, and broken down to reuse in good-as-new products – is a popular strategy in the aviation sector, in which ongoing monitoring, maintenance and redeployment of high-value equipment such as turbines is crucial.

While the chemical industry is working hard to make changes, developing a circular model presents extra hurdles. Chemicals tend to be consumables and are difficult to recover once utilised. For example, it would be near impossible to retrieve fertilisers from the ground, or shampoo from drains once they have been used. In such cases, the focus needs to be on ensuring the raw materials used in production are more sustainable.

There are examples where progress has been made. Unilever’s production of a surfactant from the industrial emissions produced by a steel mill in China is particularly innovative. Usually, surfactants are derived from fossil fuels, but this new process allows them to be made from recycled carbon, resulting in an 82% reduction in associated greenhouse gas emissions compared to the usual fossil-fuel process.

However, initiatives like these are too few and far between for a £32bn (US$43.9bn) industry that employs 500,000 people, relies heavily on oil and gas, and is the second-largest industrial emitter of carbon dioxide in the UK.

Aiming to facilitate the transition to a chemical circular economy in the UK through innovation and knowledge exchange, UK Research and Innovation (UKRI) is funding the Interdisciplinary Centre for Circular Chemical Economy led by Loughborough University, a collaboration between seven universities – including Edinburgh Business School at Heriot Watt University, and several dozen organisations operating in the sector.

UKRI Interdisciplinary Centre for Circular Chemical Economy

The UKRI Interdisciplinary Centre for Circular Chemical Economy is a newly-launched national centre as part of the £30m National Interdisciplinary Circular Economy Research (NICER) Programme in helping the UK to reduce waste and the environmental impacts of production and consumption and creating opportunities for new UK industries. The Centre aims to transform the UK’s £32bn chemical industry into a future-proof circular industry by developing sector-wide solutions for the efficient recycling and recovery of olefins and their complementary feedstocks for chemicals production. It will adopt a co-creative approach with industrial partners and stakeholders to deliver interventions and scientific innovations at all levels, starting from the development of new disruptive technologies, their integration into existing processes, and evaluation of whole system impacts to the identification of non-technical barriers and opportunities and how they can be overcome.

Whilst understanding the complex motivations and challenges to build a circular chemical economy is not straightforward, realising the key interventions that should be implemented is even more difficult. To provide stakeholders with co-created knowledge on these issues, we ran two workshops with more than 90 participants from prominent businesses in the chemical industry – from multinationals to SMEs, academia, and third-sector organisations across the globe. Here are some stakeholders’ perspectives we gathered from the two workshops on how to build the future circular chemical economy.

Business motivations to engage with the circular chemical economy

Unanimously, the biggest motivation for our industrial partners to shift towards a circular economy is the current unacceptably high carbon emissions associated with the sector. It’s become commonly accepted that the chemicals sector does not have the option of business-as-usual as we transition to net zero, because the current linear approach is simply incompatible with UK emissions and clean growth policies.

Another key driver for chemicals producers and users to engage with the circular economy is public and media pressure in favour of more sustainable products, particularly among consumer-facing companies. However, action does not always match the rhetoric. Resistance to change can actually be a major barrier to the viability of more sustainable solutions.

A supermarket partner pointed to a trial in which single-use plastics were removed from the packaging of cherry tomatoes. Although this was a direct response to customer feedback, the result was that shoppers perceived the tomatoes to be less clean, and as a result, waste increased by 20%, with knock-on effects in the form of food waste and a negative commercial impact on the store.

This serves as a timely reminder that economic viability is a fundamental condition for businesses to engage with the circular economy. Although most businesses do genuinely want to do the right thing, it can be difficult for them to implement changes if consumer behaviour does not necessarily reflect their stated preferences and new solutions are not therefore commercially viable. On the other hand, it also requires the supply of more sustainable raw materials, or feedstocks, at the right price and in sufficient quantities.

Economic viability can also be impacted by government policy. For instance, it ensures a business case and level playing field are created through all market participants facing the same penalties for failure to follow. However, it is vital for policies to remain stable to give business the confidence to adopt new technologies that facilitate improved chemical recycling processes, and accelerate the supply and demand for more sustainable raw materials, among other circular practices.

A stable policy is also essential to developing financial incentives to implement new technologies, which already face funding challenges given that much of the petrochemical and chemical industry is currently locked in by the significant investments that were made in fossil-based infrastructure in the past. It is a substantial financial burden on businesses to invest extensive resources in infrastructure before it reaches the end of its natural life.

What challenges are getting in the way of the circular chemical economy in the UK?

It is evident from the conversations we have had with industry participants that there are several structural challenges currently acting as obstacles to progress on this front. Significant work and resources will be required to transform the UK chemical industry’s linear supply chain model into a fossil-independent, climate-positive and environmentally friendly circular economy.

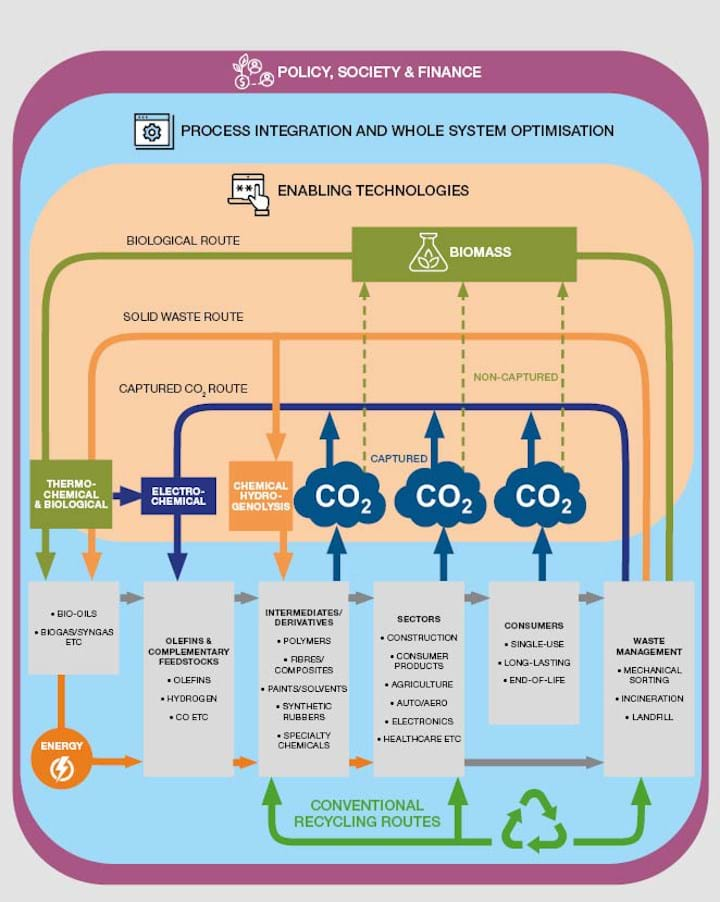

It is widely recognised that some technological barriers persist, as there is a need to develop new materials from sustainable feedstocks and to create new chemical recycling processes to allow a wider range of materials to become recyclable. That’s why within our Centre, we are advancing a portfolio of transformative technologies, ranging from hydrogenolysis to convert currently non-recyclable polymer materials into short-chain hydrocarbons, to the electrochemical transformation of captured CO2 emissions from industrial sources into olefins, driven by renewable electricity, and to hydrothermal liquefaction to enable the recycling of waste biomass and plastics mixtures.

The technological and operational challenges are interrelated to the issue of feedstocks, as it is difficult to source renewable feedstocks (or raw materials) with the levels of purity and cost required to conduct their processes at scale. Several participants from downstream manufacturing identified the need to increase the quality of final recycled products and to cut the overall carbon footprint throughout the product lifecycle.

The current construction of new incineration facilities would be counter-productive to chemical recycling, due to long-term contracts being put in place to guarantee a constant input of raw materials from recyclable waste to those facilities.

What is clear is that there is no silver bullet solution to delivering a circular chemical economy. Instead, it’s a complex landscape that will require a whole system approach, bringing in all actors – businesses, policymakers, consumers, financiers,

and innovators – to deliver the change that is required. And, as with other industries, it will likely be accelerated by the increased competition and innovation that comes from challenger SMEs entering the market with new ideas and technologies.

The question for now is: where would efforts by trade groups and policymakers be best focused on addressing the various challenges the chemical sector faces in creating more circular solutions?

Some of the industrial partners in the chemical manufacturing sector we spoke to stressed that they would benefit from getting advice on the best technologies for their products and market needs, while others said they need evidence from independent research looking at the whole system to support the push for regulatory change.

In such a complex system, collaboration between all stakeholders is key to effect the required change and co-create solutions that lead to truly sustainable circular ecosystems... decisions on the best way forward need to be taken sooner rather than later

However, as one SME participant pointed out, this presents a chicken-and-egg dilemma. Changes to policy can incentivise the recycling and utilisation of recycled products. But policymakers need data to justify the policy. And to gather data, we need the process to unfold, and we need society to start taking these recycling actions. So, what comes first, the policy or the action from the public to recycle?

In such a complex system, collaboration between all stakeholders is key to effect the required change and co-create solutions that lead to truly sustainable circular ecosystems. However, decisions on the best way forward need to be taken sooner rather than later, the chemical industry does not have time on its side.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.