Nuclear Waste Disposal: The Defining Chemical Engineering Challenge of Our Time?

Steve Reece of Nuclear Waste Services on the challenges of developing a geological disposal facility

NUCLEAR technology has been part of our lives in the UK for over 60 years. It provides around 15% of the UK’s electricity and is used across industry, medicine, and defence. And, if the UK government’s ambitions are realised, we will soon come to rely on it even more as a source of energy. As a result of historic nuclear energy generation we have a legacy of radioactive waste, some of which we need to continue to manage safely today and for the thousands of years that it will remain a hazard.

Delivering a safe, secure, and permanent solution for higher-activity radioactive waste represents one of the most significant challenges and opportunities of our time. And its complexity is underlined by the wide range of engineering and technical expertise required.

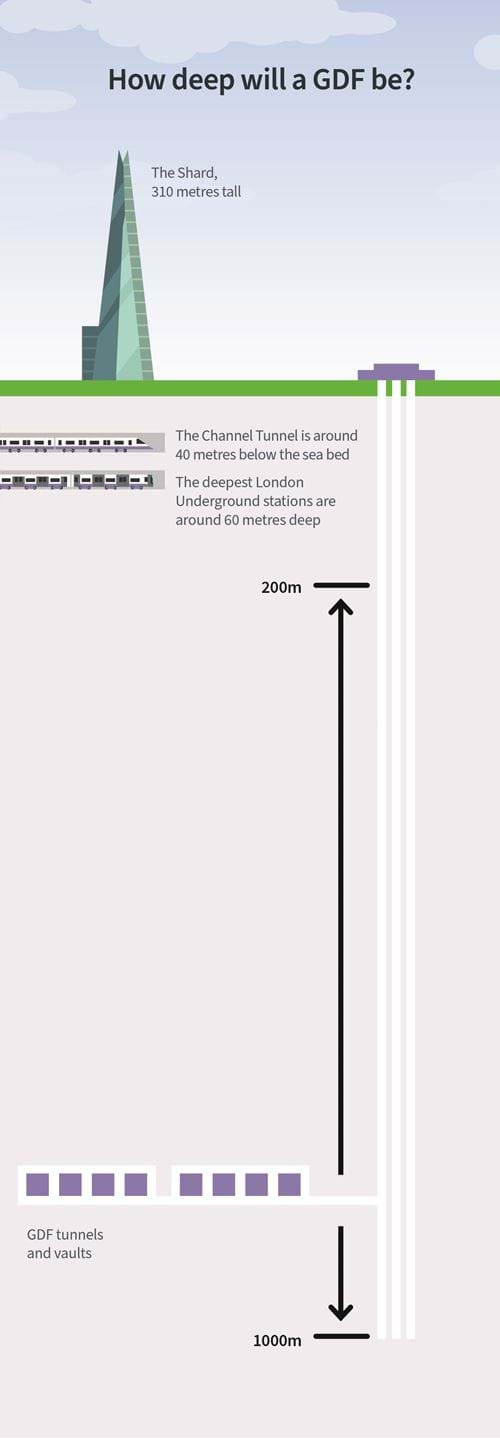

Development of a geological disposal facility (GDF) is the only viable, internationally accepted solution to managing the most radioactive waste in the long term. This underground facility, which is designed to dispose of radioactive waste in highly engineered vaults and tunnels deep underground, will be housed within suitable geology potentially three times deeper than the height of UK’s tallest building, the Shard, in London.

As an indicator of the sheer scale of this challenge, we expect to have more than 4m m3 of waste to manage to complete the UK’s decommissioning programme, with over 770,000 m3 of higher activity waste destined for a GDF.

While radioactive waste can be safely stored above ground, these facilities require ongoing maintenance and need replacing every 50-100 years. Investing in a GDF removes these issues entirely, offering a permanent solution for the thousands of years it takes for radioactivity to naturally decay.

Development of a GDF has been part of the UK government’s policy to manage radioactive waste since 2006 and will be one of the biggest infrastructure projects in the UK with an expected cost range of £20bn-53bn (US$25bn-67bn) and spanning 175 years.

What part will chemical engineers play?

Chemical engineering will play a central role in the entire lifecycle of a GDF, from the packaging of nuclear waste to analysing how it interacts with the geology and design of the facility. And with such a long lifecycle for a GDF, the key challenges will be maintaining a healthy pipeline of professionals, understanding the complex ecosystem of processes impacting waste during this time, and adapting to emerging technologies over this period.

One current example of this technological challenge relates to the treatment of waste, a critical step in the process, immobilising or removing its radioactivity before packaging. For chemical engineers, the ambition is to do this in a way that reduces the waste volume as much as possible while remaining safe. Thermal treatment has been identified as an effective approach. Through the application of a high temperature and combining the waste with glass-forming additives, this process digests waste into glass, destroys organic material, and oxidises metallic components. The result is a product that is at minimum volume but highly durable, making it an ideal solution for waste disposal in a GDF; lower volume means less space required and therefore reduced construction costs. This technology is not currently in use for the treatment of nuclear waste in the UK. However, there is a wealth of international experience in the application of this technology, and a programme of technology maturation, including pilot scale trials, which are underway in the UK. This is being led by Nuclear Waste Services and delivered by Sellafield Limited on behalf of the Nuclear Decommissioning Authority. This is one example of how chemical engineers and the wider project team need to factor future technologies into the planning process for a GDF.

Its long lifecycle makes the GDF an unusual infrastructure project. The building and filling of the facility will be completed in a staged way, spanning many decades and leaving plenty of opportunity for new solutions to be developed and applied. A key challenge for chemical engineers is to demonstrate how we can create a GDF using today’s technologies within today’s regulation, while remaining adaptive and responsive to progress.

A vital element of this role is showing that the geology of a chosen GDF site is appropriate for the disposal and storage of nuclear waste. This challenge lies at the interface of material science and chemical engineering and involves understanding the complex, dynamic processes that take place over the thousands of years it takes for the waste to decay.

According to the current solution, once nuclear waste has been treated and packaged it will be moved into an underground tunnel or vault and surrounded by a clay or other material. This arrangement is designed to protect the waste package for as long as possible, but chemical reactions and processes over thousands of years could impact the integrity of this system and engineers must feel confident that this does not pose a threat to the adequate containment of radioactivity. Engineers must therefore be able to understand and model the hydro, thermal, mechanical, chemical, and biological processes, which are constantly changing and have the potential to impact safe storage of nuclear waste.

The ecosystem and interaction of these processes is hugely complex. For example, water infiltration and egress (hydro) is compounded by compression from the host rock (mechanical), while the waste package has a thermal output, which decreases over time (thermal). Meanwhile, chemical reactions, from corrosion to absorption, are taking place (chemical) and the unique biology of a host site must also be considered (biological).

Engineers for this project need to be able to model these processes from an atomic scale, which is fundamental chemistry, but also up to a waste package scale, which encompasses a much broader engineering understanding. While international GDF efforts in the likes of Sweden, Finland and France have built a solid body of knowledge, the unique inventory and geology of a UK-based project means that much of this work is yet to be done.

Therefore, chemical engineers will require a unique skillset to succeed in this project. While a sound understanding of the subject matter is a prerequisite, they will need a mindset of integrating broader engineering principles into a wider systems optimisation to achieve the GDF solution. This is a project with the potential to offer unique opportunities for generations of chemical engineers.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.