Giving a Client Value: Whatever That Is

John Downer explains how teams can understand and provide value to projects for clients

WE ALL seek good value in everyday life and often use expressions like “value for money” to distinguish between options. What then is the “value” in “value for money”, when it is easy to recognise the cost of something, but we lack any precise metric for value?

In engineering, if you are planning to invest in a large plant construction project, it will be useful to start with the question of what represents value for you, the client, at the very outset, rather than once it is completed.

We all want products that are well manufactured, good quality, cheap and do not harm the environment, and those same factors are often present in much larger investments, but can be harder to see – probably due to size and scale of the venture, coupled with the involvement of multiple specialist teams that focus mainly on specific parts of the project.

Projects can often be judged as less than successful, eg due to unforeseen rises in costs, delays in delivery, or stalling. Conversely, they may be judged a success by common parameters such as cost and time, but overall be deemed a failure due to some tangential issue that may cause unacceptable social or environmental damage that contributes negatively to the project’s value. There is often a need to demonstrate value for money, but this is difficult when there is no definition of what “value” specifically represents.

Are there any existing methods or techniques that can help project teams understand what value is for a project and thereby aid its delivery? Fortunately, the answer to this question is yes.

Analysing value

Practitioners of value management remain a well-kept secret, much like the modern-day originator of thinking on value, Lawrence D Miles. Miles worked in the US for General Electric and he, along with his methods, remained an industrial secret for decades, due to the benefits it brought GE, before the techniques of value management, as it became known, finally broke out into the wider world.

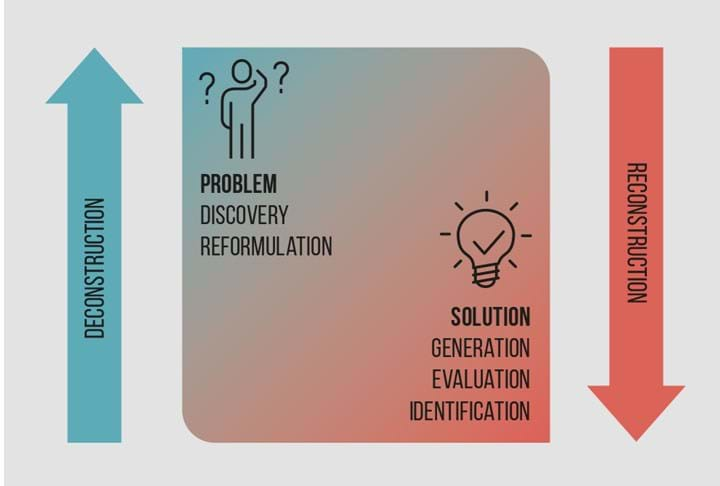

Avoiding a lengthy description of systematic techniques, the principal stages of value management can be summarised in Figure 1.

The project is deconstructed using facilitated questioning and then rebuilt with a new integrated awareness of value imparted by a value-trained facilitator. Deciding what is subjective value for the project is down to the workshop participants, based on their understanding combined with the guidance of the facilitator. This process is of immense benefit to a multi-discipline team in gaining a completely different appreciation of “their” project.

The pursuit of value via a purposeful workshop should also not be a surprise; HSE issues are rigorously pursued via hazard and operability studies (HAZOPs) and similar reviews – it is not left to chance that HSE risks will be found and dealt with as part of project development. In the same way, value is too important to hope that elements of it will permeate the project and deliver value improvement by some form of osmosis.

Techniques to understand and then add value to a project have been tainted too often by crude cost-cutting methods. Such methods are solely focussed upon ideas to reduce project cost with no consideration of the effects on project value.

What makes value?

Value is a strong concept by virtue of its need to be defined – and redefined afresh for each project and circumstance. Value management, in its origins where the focus was on factory-made products, regarded value as being derived from four main elements: use; cost; esteem; and transfer.

An improvement to value would be represented by an increase in one or more of these components of value.

The relevance of esteem and transfer are open to debate; some projects such as headquarters buildings with a need for prestige or a build, own, operate and transfer (BOOT) project featuring a literal transfer of assets can still find a use for such items. However, for a project, the deeper definition of key subjective components of value is of high utility as it supports a team’s deeper understanding of what value means for its project. It is easier to demonstrate this contention with some examples from real-life projects, anonymised as appropriate.

The majority of projects that I have facilitated to identify and then improve value are major oil and gas investments typically with a large investment cost, eg up to US$5bn. The initial phases of the value management workshop consist of a shared discovery and definition of the project itself: what its objectives are, the issues, risks, questions and other relevant challenges or concerns. This phase enables the team to hear each member’s subjective viewpoints, whilst building a new understanding as a team for the project framed in a dialogue of value.

Out of this foundational work, leading questions are posed to ask what is of value to the client? The shared debate on that is of as much benefit as the later stage of bringing forth suggestions. For many projects, cost will be to the fore; all projects will have safety issues as a requirement. Then, interestingly, other items such as maintainability, constructability, client image, minimisation of environmental impacts, and other previously little-considered factors often surface as important for project teams, based on their shared understanding acquired during the workshop. Identifying these for your specific project is key.

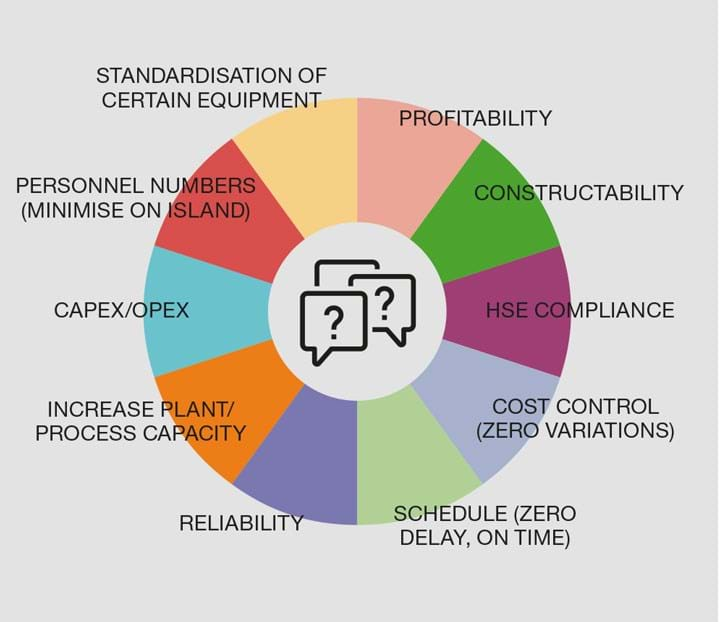

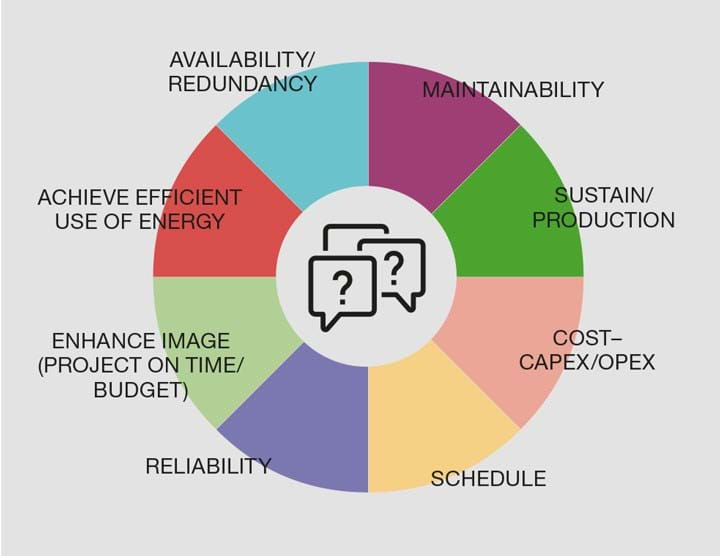

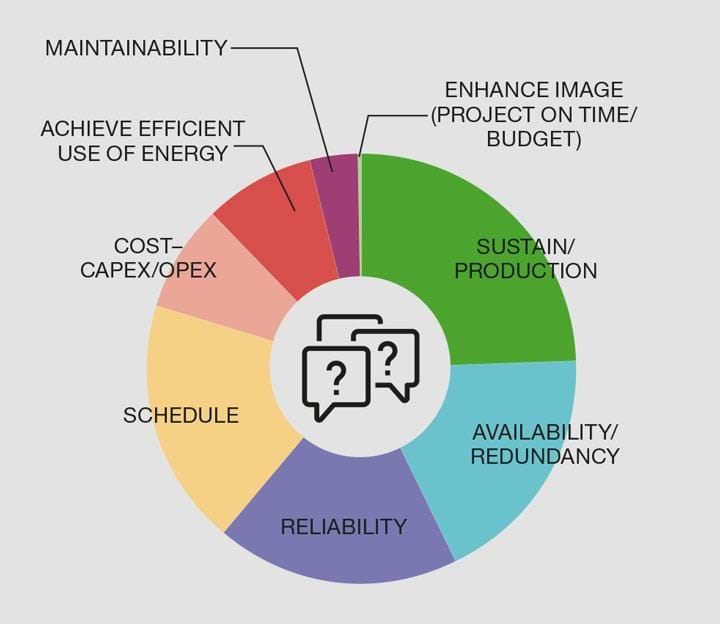

Figures 2–4 illustrate the outputs from some workshops I have run where, working with large teams, we’ve considered the value for a particular project.

In Figures 2 and 3, the components of value as agreed by the workshop participants are shown as having equal importance (unweighted). If time permits and the team wish to do so, it’s possible to use additional techniques to weight the components and uncover their relative importance.

In Figure 4 the components have been weighted. It is particularly interesting to see how cost comes some way down in terms of priorities here and highlights that, for that project, the sustainability of production was pre-eminent.

The figures do not describe anything unusual or strange. All listed items are significant, as they have been uncovered by the team and this provides ownership and relevance. There is no ambiguity about knowing what value for money is – it would be anything that improves any one or more of these agreed components. It also means that in a subsequent stage of idea generation in a value workshop, ideas to improve the value of the project can be directly linked to areas of value for a client. This ensures a “block-chain” link of creative ideas to improve the project to value components.

These value-adding strategies have led to many clients implementing mandatory procedures that specify a value workshop for all projects above a threshold value.

The value of value management

A project can be viewed in engineering terms as a range of possible options, each maybe with different responses to the applied constraints and forces. The same project viewed from a value perspective will respond to the same engineering constraints but additionally strive to find the most appropriate solution to satisfy the other components of value. This is where value management distinguishes itself by leading to the discovery of ideas that can lower costs, reduce time, improve quality and satisfy other criteria such as environment, constructability, public image etc. It has additional spinoff benefits of educating engineering teams in ways of delivering design solutions that are better value and lower cost.

The clearer a client can be on what value is for them on a project, the better the chances of a project outcome that is optimal in terms of cost and many other value components such as schedule, constructability, maintainability, environmental etc.

Value management has a long proven history of delivering better projects often at savings of 20% less than initial estimates and I have had personal experience of developing ways of improving projects where as much as 80% of cost has been removed. And here’s the punchline: with no loss of project functionality, quality etc.

Therefore, to deliver better value, time and effort should be spent exploring and understanding a project’s value. The good news is that there are proven techniques that exist and can help. Once there is an understanding of what represents value there is an excellent chance that an aligned, facilitated team can work towards finding ways to increase it, and thereby deliver real value for money.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.