Using a sponge made of pollen to soak up oil from contaminated water

A POLLEN-BASED sponge has been developed as a more environmentally friendly way of soaking up oil and other organic solvents from contaminated water.

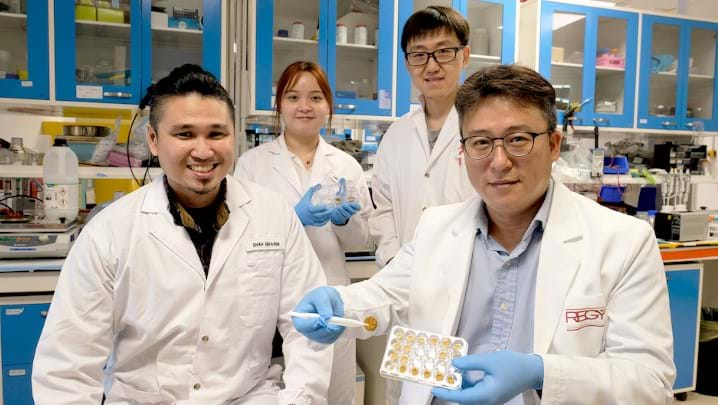

Conventional oil spill cleanup methods can be expensive and may worsen the damage. Now a research team from Nanyang Technological University Singapore and Sungkyunkwan University in South Korea have developed a sponge made from pollen that could offer a more sustainable solution.

The sponges that can be used to clean up marine oil spills are useful in numerous industries including healthcare and energy due to their properties, such as being low density, having a high surface area, and a high absorption capacity. However, they are typically made from synthetic polymers, which has raised concerns over their environmental impact.

Pollen is a renewable feedstock that has ideal properties as a material, however until recently it was thought that pollen grains weren’t pliable due to a hard outer layer which led them to be called the “diamond of biopolymers”. Previous work by the research team showed that pollen can be converted into microgel with a process that adjusts the mechanical properties of the pollen shell layers.

Cho Nam-Joon from the NTU School of Materials Science and Engineering, who led the study said: “Pollen that is not used for plant pollination is often considered biological waste. Through our work, we try to find new uses for this ‘waste’ and turn it into a natural resource that is renewable, affordable, and biodegradable. Pollen is also biocompatible. It does not cause an immunological, allergic or toxic reaction when exposed to body tissues, making it potentially suitable for applications such as wound dressing, prosthetics, and implantable electronics.”

Pollen grains from sunflowers are covered with “pollen cement” which is made from lipidic components. The researchers removed this by rinsing the grains with water, acetone, and diethyl ether. The grains were refluxed in an aqueous potassium hydroxide solution (KOH) to remove the inner part of the grain, which left only the shell of the pollen grain. The shells were incubated in KOH and then freeze-dried. This created the pollen sponges with 3D porous architectures. The sponge was heated and then incubated in an ethanolic solution containing stearic acid. Coating the sponge in stearic acid – which is a common fatty acid found in nature – causes it to become highly hydrophobic.

Sponges need to be compressed to release the oil before they can be reused. This was tested and it was found that after 100 cycles, the sponge retained 92% of its original height with 20% compressions, and 59% of its original height with 60% compression.

The sponges can absorb oil of different densities and was tested on a variety of oil including gasoline, pump oil, and n-hexane. The team tested the sponges for ten cycles to show that they could repeatedly absorb and release oil.

The sponge could absorb 9.7–29.3 g/g, which is comparable to commercial polypropylene absorbents which have a capacity range of 8.1–24.6 g/g.

“Collectively, these results demonstrate that the pollen sponge can selectively absorb and release oil contaminants and has similar performance levels to commercial oil absorbents while demonstrating compelling properties such as low cost, biocompatibility, and sustainable production,” said Cho.

The sponges engineered so far are 5 cm in diameter but the team now plans to scale up the size of the sponges to meet industry requirements. They are also looking to collaborate with NGOs and international partners to conduct pilot tests in real-life environments.

“We hope our innovative pollen materials can one day replace widely-used plastics and help to curb the global issue of plastic pollution,” said Cho.

Advanced Functional Materials https://doi.org/gfkj

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.